Quality

- Quality System

- Fabric Combustion Testing

- ILD Testing

- Endurance testing

- Welding Penetration test

- Torque test

- Universal tensile testing

- Faro arm testing

- Hardness Testing

Fabric combustion testing

Combustion test is the flame/ fire test of fabric. Fabric can burn and we check it stages where it stand because in razi sons (Pvt.) ltd we consider our customer safety first

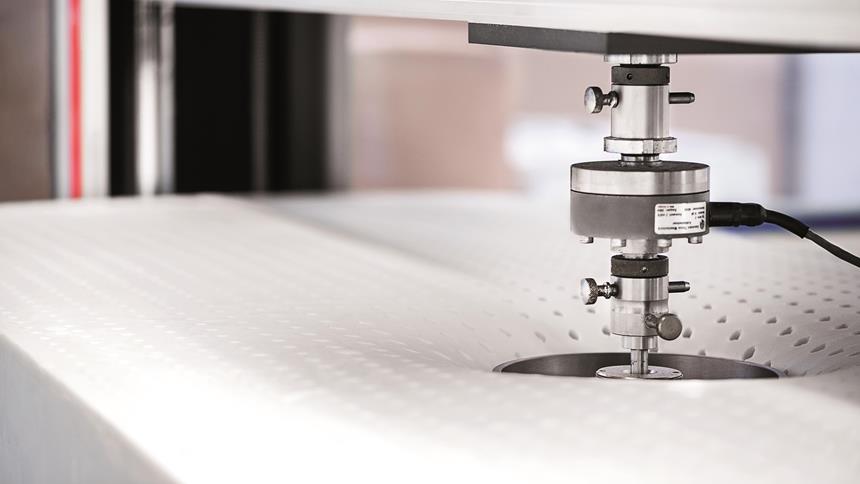

ILD Testing

Indentation Load Deflection or ILD test machines feature ASTM compatible test software and test reports and are outfitted with the required compression platens that will help you meet your requirements. Our modular ILD test machine and foam test equipment is used for both foam research and manufacturing for quality.

Endurance testing

The goal is to discover how the system behaves under sustained use. That is, to ensure that the throughput and/or response times after some long period of sustained activity are as good or better than at the beginning of the test.

Welding Penetration test

We are Razi Sons (Pvt.) Ltd equipped with state of the art welding robots and machines but there need to be check at any stage in this where welding penetration testing came into its existence we check all of our product joints to check its build quality to maintain the status of product

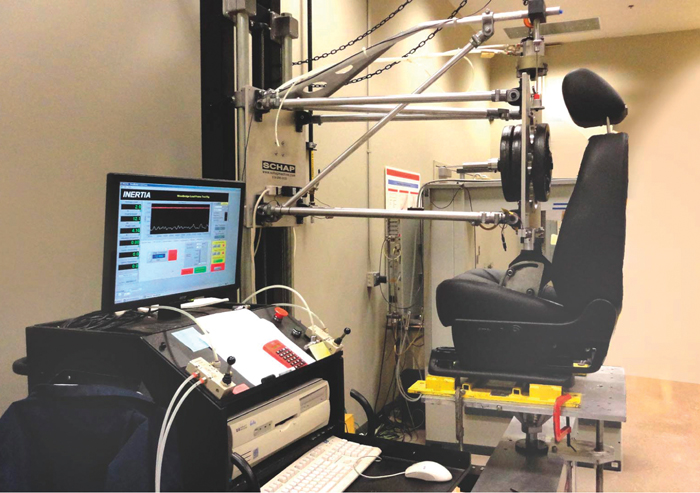

Torque Testing of automotive seat is most important parameter for Razi Sons and has been always demanded. Failure of seating system is

directly impact in warranty & service claim cost. So the seating system ensure by various aspects like strength, comfort,

durability, etc before sending the mass production

Universal Tensile Tester

Razi Sons testing machines are used to determine the tensile strength, compression, flexural (bending), peel, shear, tear and seal strength for various materials using relevant ASTM & ISO methods. Our comprehensive range of Universal Testing Machines includes an extensive portfolio of grips/fixtures, load cells and many other accessories. All universal testing machines can be modified as required to suit individual requirements.

Faro arm testing

Faro arm testing is the new way to test the measures of product manufactured in our facility we check every single corner of product to insure that it finish product will be up to standard and due to advance reporting we are enable to check each and every defect of product

Hardness Testing

Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the indentation. More simply put, when using a fixed force (load) and a given indenter, the smaller the indentation, the harder the material.